Why Fibre Cement Boards Are Better Than Other Options?

Nowadays there are a lot of elements available which can be used for exterior wall cladding like metal, brick, gypsum and fibre cement boards. In between all these things, the fibre cement boards are widely used. Here before purchasing any material, the buyer should understand that most of the elements look same from the surface. This can lead to unnecessary confusion. Here the buyer should also understand that the difference is of chemical composition. Because of their superb chemical composition and their benefits, fibre cement boards are becoming more and more popular. Let us see some more things about fibre cement boards.

Manufacturing material: The fibre cement boards are made up of quartz sand and reinforced fibre. Reinforced fibre is responsible for the actual strength of the fibre cement boards. That’s why they last for so long. In comparison to the gypsum boards, they are made up of plaster pressed between papers. In between both of them, the fibre cement boards are much more efficient and long-lasting. Going deep in the technical language, that’s because of the mesh-like molecular structure which provides strength and flexibility to the output sheets.

Resistivity property: Outer surfaces have to face some extremely harsh conditions sometimes due to bad weather. The temperature variation also affects a lot. Basically, they have to deal with the three things i.e. heat, wind and water. Here using fibre cement boards can solve these weather-related problems. These boards are highly water-resistant. This means they can stop the growth of moulds on their surface. The fibre can absorb heat naturally. This way the exterior wall cladding with fibre cement boards can regulate the temperature according to the outer conditions. Adding more to this fibre cement boards can also be used as a sound absorbent. That’s why they are mostly preferred in the area where the division is needed.

Safe to the environment: Fibre cement boards are good for the environment in comparison to the other boards. The material involved in the making of these boards is fibre and cement which are organically produced. Except this, the installation of fibre cement boards needs professional's assistance. Thus, Investing in fibre cement board is a wise choice.

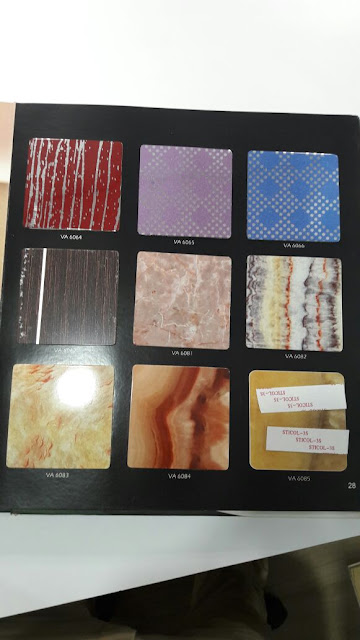

If any user wants to understand the basic comparison with the prelaminated MDF board then the data below can help. First of all, a basic particleboard is manufactured. This is manufactured from combination of glue and wooden chips. The glue and chips are compressed in the presence of heat. After this, the board is ready and can be cut into the sizes as per need. In the second half of the process, the board is covered with the lamination or veneers. This way variety of the board's increases. To provide more durability, medium density fibre (MDF) high-density fibre (HDF) is added. That’s because the plain MDF board are weak and have the chipping issue. They can be used in areas like kitchen, shelves wardrobes etc. If the demand is to avoid moisture and maintenance of hygiene then the acrylic solid surface is the best choice.

Comments

Post a Comment